How Are Bridges Built? Full Guide to Modern Bridge Construction

Bridges have always played a key role in human progress. From wooden footpaths in ancient villages to massive modern steel giants, they’ve helped people connect, travel, and grow. In the past, bridges were made with basic tools and materials—like stone, wood, and rope. Later, new ideas and technologies made it possible to build bigger and stronger ones, such as the Roman aqueducts or the iron bridges of the Industrial Revolution.

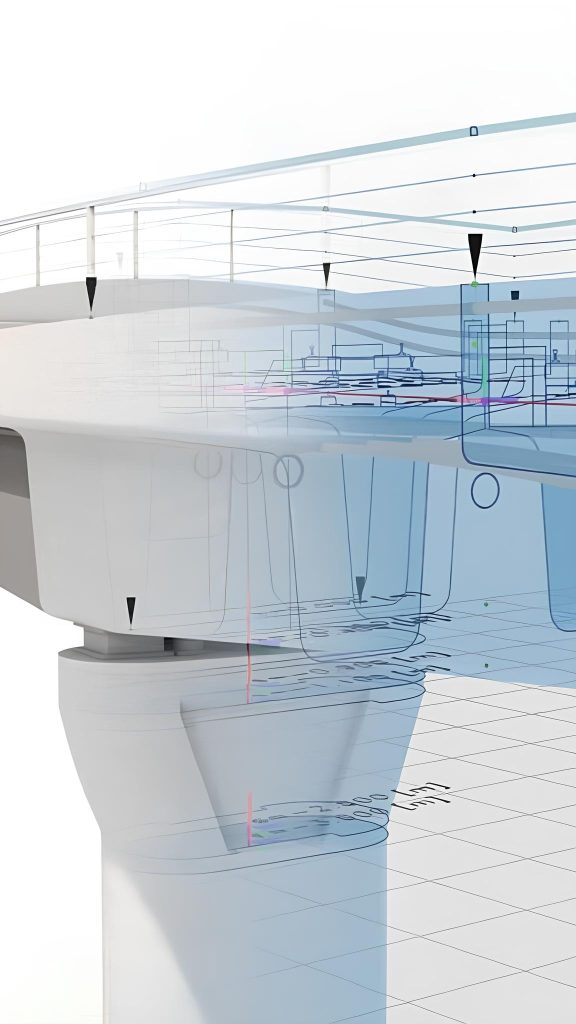

Today, bridges are not just about crossing from one place to another. They are also symbols of smart engineering and modern design. Every bridge we build must be strong, safe, and long-lasting—especially in places with heavy traffic or harsh weather. So, how are these huge structures actually built?

Let’s explore the main steps of building a modern bridge.